Most powerful solar panels 2024

In the solar world, panel efficiency has traditionally been the factor most manufacturers strived to lead. However, over the last 3 to 4 years, a new battle emerged to develop the world’s most powerful solar panel, with many of the industry’s biggest players announcing larger format next-generation panels with power ratings well above 600W.

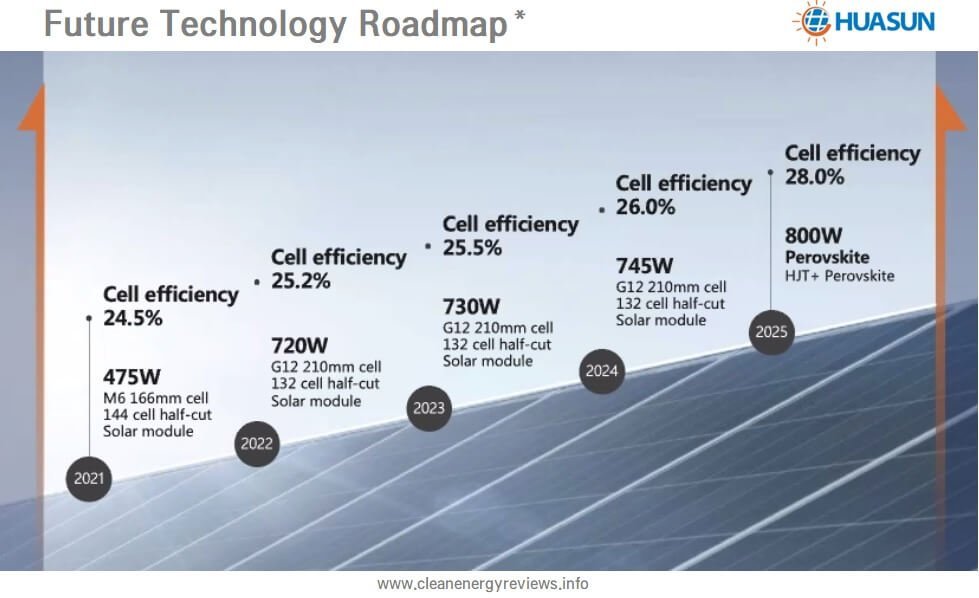

The race for the most powerful panel began in 2020 when Trina Solar revealed the first panel rated at 600W. Not long after, at the SNEC PV Power Expo in China, JinkoSolar unveiled a 610W version of the Tiger Pro panel. Around the same time, Trina Solar announced that a more powerful 660W+ panel was in development. Amazingly, close to 20 manufacturers at SNEC 2020 showcased panels rated over 600W. From 2020 to 2023, power and efficiency records were regularly broken as manufacturers continuously out-competed each other using new module formats and more efficient cell technologies. Now, in 2024, many manufacturers have released panels rated well above 700W, with plans to develop panels surpassing an incredible 800W within the next 2 years.

Despite the publicity around the many high-powered panels, the PV cell advancements enabling these higher power ratings are universal. Thanks to these innovations, regular-size commercial and residential solar panels have also increased in power significantly, with 400W to 550W panels now standard. The considerable increase in power is primarily due to increases in efficiency thanks to many innovations, which we describe later in the article.

Designed for utility-scale systems

The main driver for developing larger, more powerful solar panels stems from the desire to decrease the cost of utility-scale solar farms and ultimately reduce electricity prices. Since larger panels require an equivalent amount of connections and labour compared to smaller panels, the installation cost per kW is reduced, resulting in lower overall cost and decreased LCOE. As explained below, high-powered panels are far larger than those used on residential rooftops. Those wishing to use ten 700W panels on their home rooftop to get an easy 7kW will be a little disappointed. At this stage, most high-powered panels are only available for commercial and utility-scale systems, plus the extra-large panel sizes are not compatible and are very challenging to handle on most residential rooftops.

Interestingly, premium module manufacturers SunPower (now Maxeon) and REC are not racing to develop larger format high-power panels for utility-scale applications. Instead, these companies are focused on supplying their traditional residential and commercial customer base with compact-sized, high-efficiency panels.

Power Ratings Surpass 700W

The utility solar industry has been slowly shifting towards larger, higher-wattage panels, with the front runners in the race traditionally being Trina Solar, Jinko Solar, Canadian Solar, Risen Energy and JA Solar. These huge, well-established companies were the first to manufacture high-power panels with ratings above 600W. However, throughout 2023 and early 2024, Huasun Solar, TW Solar (Tongwei), Jolywood, and the lesser-known company Akcome announced panels rated above 700W using the latest N-type TOPCon or heterojunction (HJT) cell technologies.

In the latter half of 2023, a competitive race unfolded between two huge Chinese companies, Huasun and Tongwei, both vying to develop the most powerful solar panel. Each company assembled its latest, highest-efficiency cells, striving to surpass each other. Huasun Solar emerged as the frontrunner, introducing the Himalaya G12-132 HJT (Heterojunction) module in November 2023, which achieved certification from TÜV SÜD, a prominent third-party testing and certification institution. This panel showcased a record-breaking power output of 750.54W, coupled with an impressive efficiency of 24.16%. More recently, TW Solar announced a panel with an impressive 765W power rating, but this is yet to be certified by an independent third-party.

Despite the numerous record-breaking announcements, large-volume production of most panels rated above 700W is still in the early stages as manufacturing facilities and cell production lines need to be developed. Most manufacturers have only produced small volumes of 700W+ panels for testing and verification. In the list of the most powerful solar panels below, we include all panels that have been independently verified, regardless of the production volume.

Most Powerful Solar Panels 2024 - Downloadable chart

Most powerful solar panels list for June 2024 - Refer to Manufacturers datasheets for full details.

Top 10 Most Powerful Solar Panels

List of the most powerful solar panels that have been officially announced and independently certified. Not all panels listed are in full production. Maximum panel size of 2.4m high x 1.35m wide. Availability and official release dates may vary for different regions.

| No. | Make | Model | POWER | Cell type | Efficiency % | Announc * |

|---|---|---|---|---|---|---|

| 1 | Huasun | Himalaya G12 | 750 W | N-Type HJT Bifacial | 24.16 % | Q4 2023 |

| 2 | TW Solar | 210-66HJT | 744 W | N-Type HJT Bifacial | 23.94 % | Q4 2023 |

| 3 | Trina Solar | Vertex N | 740 W | N-Type TOPcon Bifacial | 22.5% | Q3 2024 |

| 4 | Risen Energy | Hyper-Ion | 740 W | N-Type HJT Bifacial | 23.89% | Q3 2023 |

| 5 | Akcome | iPower 7 | 720 W | N-Type HJT Bifacial | 23.2 % | Q4 2023 |

| 6 | Canadian Solar | TOPHiKu7 | 720 W | N-TypeTOPCon Bifacial | 23.2 % | Q2 2024 |

| 7 | Recom Tech | ALynx Series | 720 W | N-TypeTOPCon Bifacial | 23.2 % | Q2 2024 |

| 8 | Jolywood | JW-HD132N | 700 W | N-Type TOPCon Bifacial | 22.5 % | Q4 2022 |

| 9 | SunTech | Ultra X Plus | 700 W | N-Type TOPCon Bifacial | 22.5 % | Q3 2023 |

| 10 | EGING PV | Aurora Pro | 685 W | N-Type TOPCon | 22.0 % | Q2 2023 |

* Official date of announcement or certification. The official production release date is yet to be determined.

Top 10 Most Efficient Commercial Solar Panels

Following our list of the most powerful solar panels, we provided a comparison chart of the top 10 most efficient solar panels in 2024. Power and efficiency go hand in hand, but the most powerful solar panels are not always the most efficient. A panel's power rating is primarily influenced by its physical size (area), while efficiency depends on the type of solar cell and the technology used in the panel. Therefore, a larger panel may have a higher power rating but could be less efficient than a smaller panel with superior cell technology. See our detailed solar panel efficiency article.

Higher efficiency does not automatically imply that a more efficient panel is the best option for a certain commercial solar installation. The optimum panel power, size, and efficiency for a particular project are determined by the site or building area, the mounting system, wind loading, and other site-specific requirements.

Larger Panel Sizes

In the past, most increases in power came from efficiency gains due to advances in solar PV cell technology. While that is partly a driver behind the massive jump in panel wattage, the main factor is the new larger cell and panel sizes being developed together with a higher number of cells per panel. These new cell formats and configurations mean the panels have become physically larger in size. Generally, these large-format panels are best suited for utility-scale solar farms or large commercial installations.

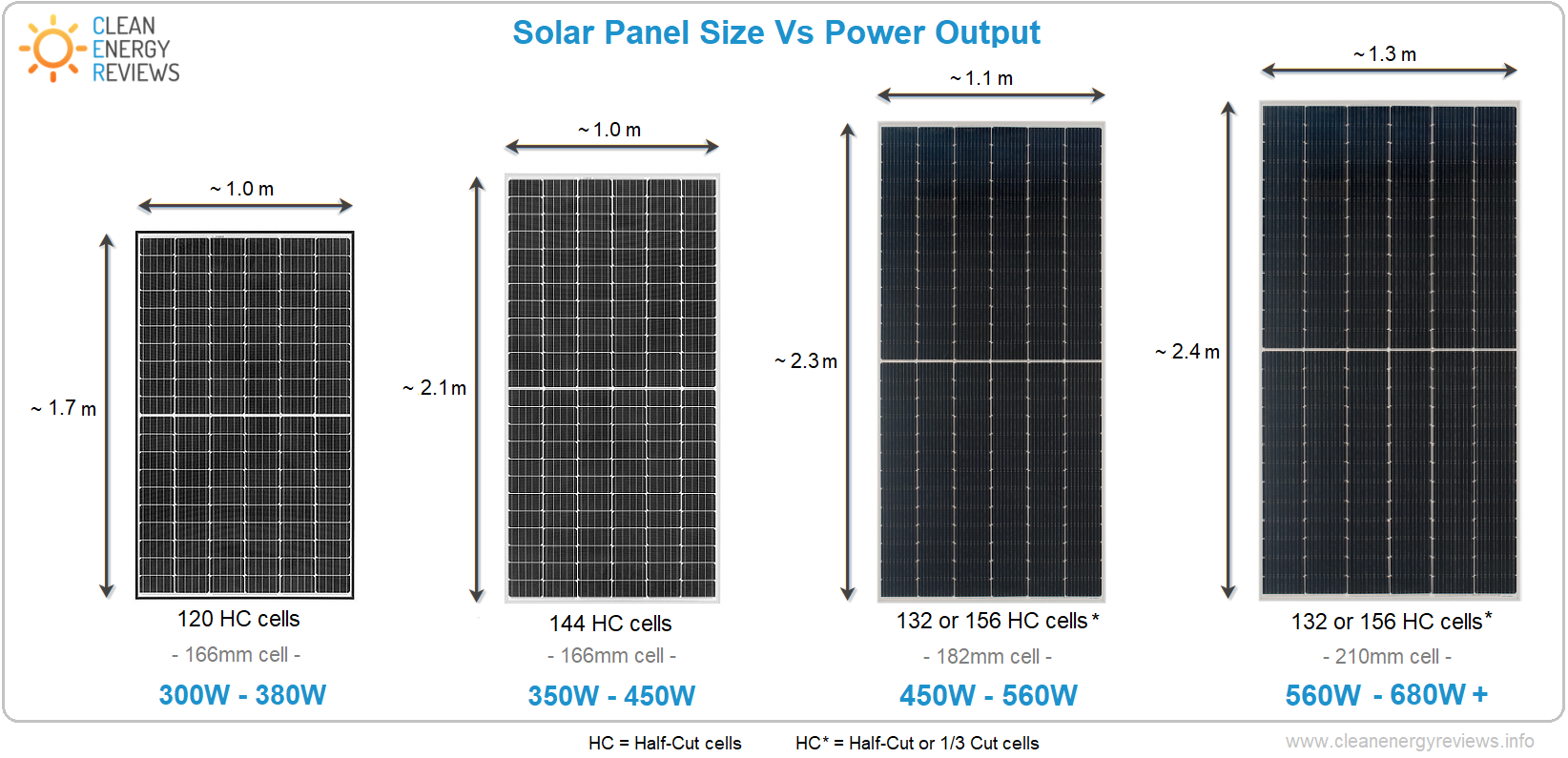

Traditionally, solar panels were available in two main sizes - the standard format 60 cell panels (roughly 1.65m high x 1m wide) used for residential rooftops, and the larger format 72 cell commercial size panels (roughly 2m high x 1m wide). Then half-cut cell panels emerged in roughly the same size but with double the amount of half-size cells at 120 cells and 144 cells. Besides the standard sizes, a few premium manufacturers, such as SunPower and Panasonic, produce unique 96 and 104-cell panels.

The industry-standard panel size for much of the last decade was built around the 156mm x 156mm or 6-inch square cell format. However, the new panel sizes emerging are up to 2.4m long and 1.3m wide and built around the larger 180 and 210mm wafer cell sizes. This is a size increase of 20% to 30% compared to the traditional 2.0m x 1.0m 72-cell panels, which naturally corresponds to a considerable boost in power.

700W+ PV Open Innovation Ecological Alliance

Trina Solar, in collaboration with Astronergy, Canadian Solar, Risen Energy, TCL Zhonghuan, and Tongwei, has introduced the 700W+ Photovoltaic Open Innovation Ecological Alliance, succeeding the 600W+ version in 2020. The alliance seeks to standardize the design and production of 700W+ solar PV modules, with agreed industry module dimensions of 2384mm x 1303mm (and long-side vertical hole distance of 400mm & 1400mm), aiming to improve supply chain efficiency, increase production, and reduce costs.

The initiative emphasizes adherence to agreed industry dimensions and calls for continuous technological advancements throughout the industry chain. Establishing standards is intended to accelerate the industrialization of 700W+ modules, promoting consistency, lowering the Levelized Cost of Electricity (LCOE), and maximizing the long-term value of solar PV.

Larger Solar Cell Sizes

To decrease manufacturing costs and gain efficiency, most manufacturers moved away from the standard 156mm (6”) square cell wafer size in 2020 in favour of larger wafer sizes. While there are a variety of cell sizes under development, a few sizes have emerged as the new industry standard; these include 166mm, 182mm and 210mm. Many of the leading manufacturers, including Jinko, Longi and Canadian, aligned with the 182mm format. Trina Solar is pushing the larger 210mm wafer size, while Longi, the world’s largest mono silicon wafer manufacturer, uses 166mm and 182mm sizes, depending on the application.

To remain competitive, many smaller volume manufacturers may need to align with one of the new wafer sizes to utilise common wafer and equipment suppliers. For a complete history and insight into wafer and PV cell sizing standards, this detailed article from PV Tech examines the various wafer and ingot sizes, technology changes, and manufacturing trends around current and future PV cells.

Along with the different cell sizes, there is a myriad of new panel configurations built around the many cell combinations. The three most popular which have emerged are 66-cell (half-cut 132), 78-cell (half-cut 156), and 84-cell (half-cut 168) panels. The extra-large 210mm cells are also well suited to unique cell dividing formats such as 1/3 cut cells; where the square wafer is divided into three segments rather than the common half-cut or half-size cell.

High-efficiency PV Cells

To achieve these impressive power ratings, panels and cells have not just increased in size, but cell efficiency has improved substantially using numerous new technologies (listed below) along with more advanced rear-side passivation techniques like TOPCon.

MBB - Multi-busbars and Micro-busbars

PERC/PERC+ - Passivated emitter & rear cell

Heterojunction (HJT)

TOPCon - Tunnel-Oxide Passivating Contact

N-type silicon cells substrate

High-density cells - Reducing inter-cell gaps

Manufacturers are exploring ways to increase power and cell efficiency by spending big on research and development. N-type silicon wafers are one of the best ways to boost efficiency but have traditionally been more costly. However, the price gap between P-type and N-type silicon is reducing as the economies of scale lower the cost of manufacturing the high-performance N-type silicon wafers used as the basis for more efficient HJT and TOPcon cells. In the future, Perovskite cell technology is expected to become stable and viable, allowing manufacturers to create next-generation tandem cells with power levels up to 800W.

Chart of the current and predicted maximum solar panel power from 2021 to 2025 - Image credit Huasun Solar

MBB - Multi-busbars

Of the many cell improvements, the most common technology used to increase efficiency has been multi-busbars (MBB). Traditional ribbon busbars (5BB or 6BB) are being rapidly phased out in favour of nine or more thin wire busbars (9BB or 12BB). Some manufacturers, such as REC have even moved to 16 micro-wire busbars in the Alpha panel series. Wider cells also mean more busbars can fit across the cell surface, with 18 or even 21 busbars being integrated into larger 210mm wide cells.

Bifacial panels featuring MBB are also growing in popularity due to the increased power output by utilising the rear side of the panel to achieve up to 20% or more power (roughly 80W extra). However, bifacial panels are generally only beneficial over light coloured surfaces such as light sandy or rocky ground used in large MW scale solar farms located in more arid areas.

High-density Cells

Trina Solar Vertex panels feature 210mm 1/3rd-cut high-density MBB cells - Image credit Trina

To further boost panel efficiency and increase power, manufacturers such as Trina Solar have introduced techniques to eliminate the vertical inter-cell gap between cells. Removing the typical 2-3mm vertical gaps and squeezing the cells together results in more panel surface area being available to absorb sunlight and generate power. Manufacturers have developed a number of techniques to minimise or eliminate the gap with the most common being to simply reduce the cell spacing from around 2.0mm to 0.5mm. The reason for this gap was due to traditional larger ribbon busbars requiring 2.0mm+ to bend and interconnect the front and rear of each cell. However, the transition to using much smaller wire busbars enabled the gap to be reduced significantly.

LONGi Solar is another manufacturer that managed to reduce the inter-cell gap down to 0.6mm by using what the company describes as a “smart soldering” method using integrated segmented ribbons. This new technology uses a unique triangular busbar design across the front surface of the cell, with a very thin flattened section that bends and runs behind the cell to form the interconnection.

TR - Tiling Ribbon technology

Jinko Solar, currently the world’s largest panel manufacturer, developed what the company refers to as Tiling Ribbon or TR cells. Tiling Ribbon cell technology is the elimination of the inter-cell gap by slightly overlapping the cells creating more cell surface area. This in turn boosts panel efficiency and power output. The tiling ribbon technology also dramatically reduces the amount of solder required through using inter-cell compression joining methods rather than soldering. Shingled cell panels, such as those used in the Sunpower Performance series, uses a similar technology where overlapping thin cell strips can be configured into larger format high-power panels.

Increasing efficiency using Tiling Ribbon cell technology to remove the inter-cell gap - Image credit Jinko

Several other leading manufacturers such as Q Cells have taken a similar approach to boost efficiency by completely eliminating the inter-cell gap. However, most manufacturers have taken the more common approach and reduced the inter-cell clearance as much as possible leaving a very small 0.5mm gap; this effectively removes the gap without having to develop new cell interconnection techniques.

N-Type TOPCon silicon cells

Cells built on an N-type silicon substrate offer improved performance over the more common P-type silicon due to a greater tolerance to impurities which increases overall efficiency. In addition, N-type cells have a lower temperature coefficient compared to both mono and multi P-type cells. N-type cells also have a much lower rate of LID or light-induced degradation and do not generally suffer from LeTID (light and elevated temperature induced degradation) which is a common problem with P-type cells.

TOPCon or Tunnel Oxide Passivated Contact refers to a specialised rear side cell passivation technique that helps reduce the internal recombination losses in the cell and boosts cell efficiency. The process has been available for several years but is now becoming the new industry standard as manufacturers strive to increase efficiency and performance.