Solar Panel Construction

Solar panel technology is advancing rapidly with greater efficiency and lower prices, resulting in a huge increase in demand. However, despite the massive advancements in technology, basic solar panel construction hasn’t changed much over the years. Most solar panels are still made using a series of silicon crystalline cells sandwiched between a front glass plate and a rear polymer plastic back-sheet supported within an aluminium frame.

Once installed, solar panels are subjected to severe conditions over the course of their 25+ year life. Extreme temperature, humidity, wind and UV radiation variations can put enormous stress on a solar panel. Fortunately, most panels are well-engineered to withstand extreme weather. However, some panels can fail in several ways, including water ingress, cell micro-fractures and potential induced degradation or PID. This is why it is vital solar panels are manufactured using only the highest quality components. In our other article, Best Solar Panels, we highlight the leading manufacturers using the highest quality materials together with testing to the highest industry standards.

How are Solar Cells Made?

Monocrystalline silicon ingots made using the common Czochralski process.

Solar panels use photovoltaic cells, or PV cells for short, made from silicon crystalline wafers similar to the wafers used to make computer processors. The silicon wafers can be either polycrystalline or monocrystalline and are produced using several different manufacturing methods. The most efficient type is monocrystalline (mono), manufactured using the well-known Czochralski process.

In the past, Polycrystalline wafers were made using several purification processes followed by a simpler casting method, which was much lower-cost. However, they were also less efficient, which resulted in the phase-out of polycrystalline wafers in favour of the higher purity and higher performance monocrystalline wafers.

Monocrystalline silicon cells - Higher efficiency

Polycrystalline silicon cells - Lower efficiency (now rarely used)

Manufacturing Solar PV Cells

Manufacturing typical silicon-based solar cells requires a number of different processes, starting from a raw material called Quartzite, a form of quartz sandstone rock. First, Quartzite, or silica sand, is converted into metallurgical-grade silicon by combining Carbon and Quartzite in an arc furnace. This process occurs at very high temperatures, producing 99% pure silicon. The next step is to convert the metallurgical-grade silicon into pure Polysilicon using either a chemical purification process called the Siemens process or upgraded metallurgical-grade silicon (UMG-Si) using less costly metallurgical processes.

The basic materials and steps involved in making a monocrystalline silicon solar cell

Next, the polysilicon is doped with trace amounts of either boron or phosphorous to become either P-type or N-type silicon. At this stage, the polycrystalline silicon can be melted, cast into large rectangular blocks, and thinly sliced using a diamond wire cutting method to produce the polycrystalline or multicrystalline wafers.

To manufacture the more efficient monocrystalline wafer or cells, the doped silicon can be made into a pure solid crystal ingot using the Czochralski process. This process involves melting the polycrystalline silicon under high pressure and temperature to slowly grow a large monocrystalline crystal known as an ingot.

Steps to manufacture monocrystalline solar PV cells

Silica sand is purified in an arc furnace to create 99% pure silicon

The 99% silicon is further refined close to 100% pure silicon

The silicon is doped with boron or phosphorous (P-type or N-type)

The doped silicon is melted and extracted into a crystalline ingot

The round ingot is diamond wire-cut into thin square wafers

The thin base wafer is coated with an ultra-thin layer of either P-type or N-type silicon to form the PN-junction.

An anti-reflective layer and metallic fingers are added to the cell surface

Flat ribbon busbars (as shown) or thin wire (MBB) busbars are added

How are Solar Panels Made?

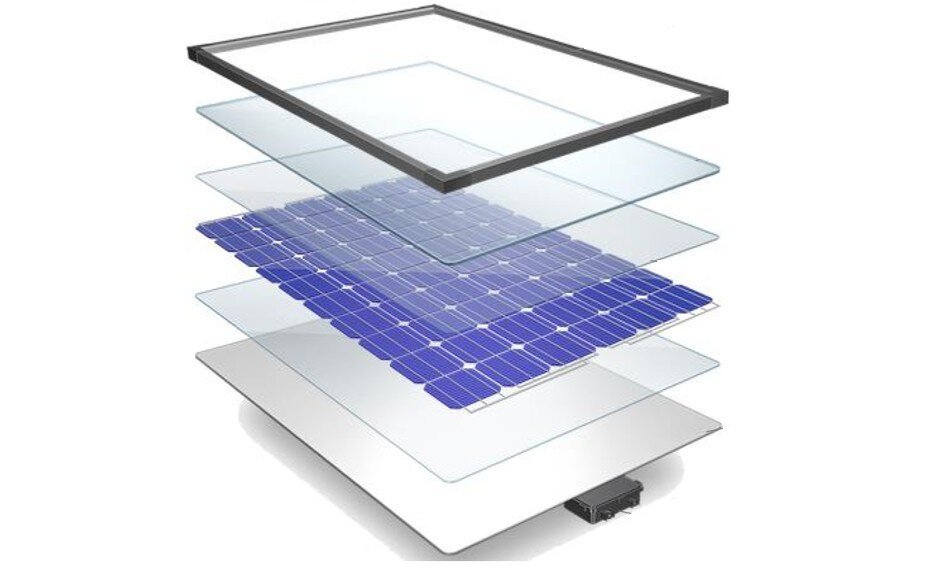

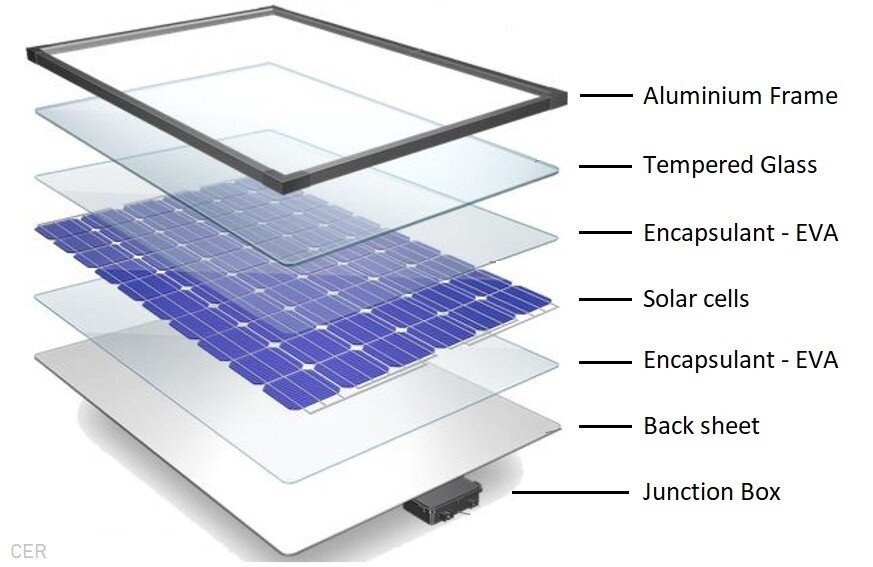

Solar panels are made using the six main components described in detail below and assembled in advanced manufacturing facilities with extreme accuracy. This article will focus on panels made using crystalline silicon solar cells since these are by far the most common and best-performing solar technology available today. Other solar PV technologies are available, such as thin film and screen-printed cells, but we will not be discussing these as they have limited use or are still in development.

Six Main components of a solar panel

Solar photovoltaic cells

Toughened Glass - Typically 3.2mm thick

Extruded Aluminium frame

Encapsulation - EVA film layers

Polymer rear back-sheet

Junction box - diodes and connectors

Many well-known solar panel manufacturers are ‘vertically integrated’, meaning that one company supplies and manufactures all the main components, including the silicon ingots and wafers used to make the solar PV cells. However, many panel manufacturers assemble solar panels using externally sourced parts, including cells, polymer back sheet and encapsulation EVA material. These manufacturers can be more selective about which components they choose. Still, they do not always have control over the quality of the products, so they should be sure they use the best suppliers available.

The 6 main components used in the construction of a solar panel

1. Solar PV Cells

Solar photovoltaic cells or PV cells convert sunlight directly into DC electrical energy. The solar panel's performance is determined by the cell type and characteristics of the silicon used, with the two main types being monocrystalline and polycrystalline silicon. The base of the PV cell is a very thin wafer, typically 0.1mm thick, and is made from either positive p-type silicon or negative n-type silicon. There are many different cell sizes and configurations available that offer different levels of efficiency and performance, including half-cut or split cells, multi-busbar (MBB) cells, and, more recently, shingled cells using thin overlapping wafer strips. For more detailed information on the different cells and solar panels types, see the complete solar PV cell technology review.

Most residential solar panels contain 60 full-size monocrystalline cells or 120 half-size cells linked together via busbars in series to generate a voltage between 30-40 volts, depending on the type of cell used. Larger solar panels used for commercial systems and utility-scale solar farms contain 72 full-size or 144 half-size cells and, in turn, operate at a higher voltage. The electrical contacts that interconnect the cells are known as busbars and allow the current to flow through all the cells in a circuit.

The 6 main types of solar panels which use different types and size solar cells

2. Glass

The front glass sheet protects the PV cells from the weather and impact from hail or airborne debris. The glass is typically high strength tempered glass which is 3.0 to 4.0mm thick and is designed resist mechanical loads and extreme temperature changes. The IEC minimum standard impact test requires solar panels to withstand an impact of hail stones of 1 inch (25 mm) diameter traveling up to 60 mph (27 m/s). In the event of an accident or severe impact tempered glass is also much safer than standard glass as it shatters into tiny fragments rather than sharp jagged sections.

To improve efficiency and performance high transmissive glass is used by most manufacturers which has a very low iron content and an anti-reflective coating on the rear side to reduce losses and improve light transmission.

3. Aluminium Frame

The aluminium frame plays a critical role by both protecting the edge of the laminate section housing the cells and providing a solid structure to mount the solar panel in position. The extruded aluminium sections are designed to be extremely lightweight, stiff and able to withstand extreme stress and loading from high wind and external forces.

The aluminium frame can be silver or anodised black and depending on the panel manufacturer the corner sections can either be screwed, pressed or clamped together providing different levels of strength and stiffness.

4. EVA Film

EVA stands for ‘ethylene vinyl acetate’, which is a specially designed polymer highly transparent (plastic) layer used to encapsulate the cells and hold them in position during manufacture. The EVA material must be extremely durable and tolerant of extreme temperature and humidity, it plays an important part in the long term performance by preventing moisture and dirt ingress.

The lamination on either side of the PV cells provides some shock absorption and helps protect the cells and interconnecting wires from vibrations and sudden impact from hail stones and other objects. A high-quality EVA film with a high degree of what is known as ‘cross-linking’ can be the difference between a long life and a panel failure due to water ingress. During manufacture, the cells are first encapsulated with the EVA before being assembled within the glass and back sheet.

5. Backsheet

The backsheet is the rearmost layer of standard solar panels which acts as a moisture barrier and final external skin to provide both mechanical protection and electrical insulation. The backsheet material is made of various polymers or plastics including PP, PET and PVF which offer different levels of protection, thermal stability and long-term UV resistance. The backsheet layer is typically white in colour but is also available as clear or black, depending on the manufacturer and module. For a detailed analysis of the various backsheet materials used, refer to the backsheet construction article from Taiyang News.

The ‘Tedlar’ PVF material from Dupont is known as one the leading high performance back sheets for PV module manufacturing.

Dual glass panels - Some panels such as bifacial and frameless panels, use a rear glass panel instead of a polymer backsheet. The rear side glass is more durable and longer lasting than most backsheet materials and so some manufacturers offer a 30-year performance warranty on dual glass panels.

6. Junction Box and Connectors

The junction box is a small weatherproof enclosure located on the rear side of the panel. It is needed to securely attach the cables required to interconnect the panels. The junction box is important as it is the central point where the cell groups interconnect and must be protected from moisture and dirt.

Bypass Diodes

The junction box also houses the bypass diodes, which are needed to prevent reverse currents, which can occur when cells are shaded or dirty. Diodes only allow current to flow in one direction, and a typical 60-cell panel is divided into 3 groups of 20 PV cells, each with a bypass diode for preventing reverse current. Unfortunately, bypass diodes can fail over time and may need to be replaced, especially if put under stress due to fixed rooftop objects causing permanent shading throughout the year - Learn more about shading and the problems with failing bypass diodes. In older panels, the cover of the junction box can be removed for servicing, although most modern solar panels use more advanced, longer-lasting diodes and non-serviceable junction boxes. You can learn more about how bypass diodes work here.

Inside a junction box of a typical 60 cell solar panel showing the 3 bypass diodes

Inside a junction box with more advanced diodes mounted to reduce heat and increase lifespan

Solar MC4 Connectors

Almost all solar panels are connected using special weather-resistant plugs and sockets called MC4 connectors. The term MC4 stands for multi-contact 4mm diameter connector. Due to extreme weather conditions, the connectors must be very robust, secure, and UV resistant and maintain a good connection with minimal resistance at both low and high voltages up to 1000V.

The connectors are designed to be used with the standard 4mm or 6mm double-insulated solar DC cable with a tinned copper multi-strand core for minimum resistance and increased durability. To correctly assemble the connectors, a special crimping tool is used to crimp the multi-strand cable to the inner terminal, which is then inserted and snapped into the MC4 housing.

Solar MC4 connectors - Male and female with internal crimped terminals

NOTE: There are several different types of MC4 connectors that may look similar but do not always fit together securely. The same type and make of connector must always be used to reduce potential water ingress or plug failure which can result in arcing and even fire. The MC4 connectors shown above and next-generation MC4-EVO-2 connectors (not shown), are both manufactured by Staubli and the only dissimilar looking connectors which are allowed to be used together.

Solar Panel Assembly and Manufacturing

Solar panels are assembled in advanced manufacturing facilities using automated robotic equipment and sensors to precisely position the components with extreme accuracy. The manufacturing plants must be extremely clean and controlled to prevent any contamination during assembly.

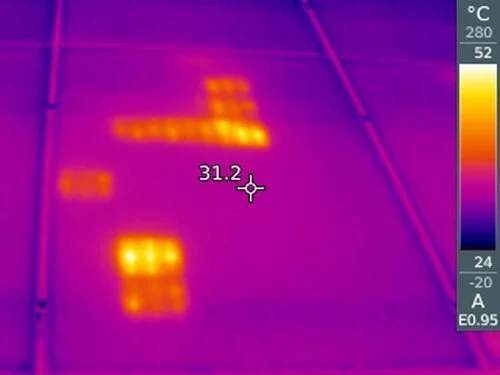

Throughout the manufacturing process, the panels and cells are checked and inspected using advanced optical/imaging sensors to ensure all the components are located correctly and the cells wafers, which are very delicate, are not damaged or cracked during the assembly process. Depending on the manufacturer, the final panel assembly is thoroughly checked using a number of tests, including electroluminescent (EL) or flash testing, to identify any defects in the cells which could lead to failure once exposed to sunlight and high temperatures for many years.

Below is a video from Tindo Solar, an Australian solar panel manufacturer.

Solar Panel Degradation And Faults

Solar panels are generally very reliable as they have no moving parts and require minimal maintenance. However, they can fail or underperform over the expected 25-year life due to several different reasons. It is normal for the cells will slowly lose power due to what is known as light-induced degradation or LID, which results in an average of 0.5% loss per year. This slow degradation is often not noticeable, and most solar panels will still perform at 80% or higher of the original rated capacity after 20 years, depending on the type of cell used. The amount of degradation is specified in the manufacturer’s performance warranty - Read more about solar panel warranties.

Unfortunately, solar panels can also suffer from more serious issues, such as micro-cracks and more severe degradation for several reasons. Any high stresses due to impacts, poor installation practices or people walking on rooftop panels can cause tiny fractures in the cell. These issues are often very difficult to detect and, if left for several years, can develop into hot spots and cause catastrophic failures such as arcing or fire. Fortunately, there are ways to reduce the likelihood of failure, and most manufacturers are improving both the panel design and manufacturing to minimise short and long-term issues. Learn more about solar panel problems such as micro-cracks and hot spots.

Sustainability

Sunlight or solar energy is a free source of renewable energy that will never be depleted. Fossil fuels, on the other hand, are finite resources that emit greenhouse gases and other particulates during extraction, processing and combustion. In comparison, solar panels do not produce emissions while in use, but they are made from several different materials that require different levels of resources and energy. The energy used to extract the raw materials and manufacture a product is known as the ‘embodied energy’. The time it takes for a product to repay the embodied energy is measured in years. This is known as the total energy payback time (EPBT).

A typical silicon crystalline solar panel will generate enough energy to repay the embodied energy within 2 years of installation. However, as panel efficiency has increased, the payback time has been reduced to less than 1.5 years in many areas with high average solar radiation.

Modern, efficient crystalline silicon solar panels generate enough energy to repay the embodied energy within 2 years. Multiple detailed studies and life-cycle analyses support this. However, many studies are outdated as solar PV cell efficiency has increased from 15% to 22% (a 45% increase) over the last few years, and payback time is estimated to be as low as one year. Considering that a typical solar panel will last 20+ years, it will easily repay the embodied energy multiple times and offset tonnes of emissions.

Are Solar panels toxic?

Despite the large amount of information circulating about solar panels being toxic, modern crystalline silicon solar panels contain virtually no toxic materials. The claims of toxic solar panels come from the mostly obsolete thin-film (Cadmium telluride - CdTe) solar panels containing trace amounts of cadmium and telluride. However, unless these (relatively rare) panels are broken up into fragments, the trace amount of cadmium is contained within the EVA layers and cannot leach out.

Modern crystalline silicon solar panels contain only traces of lead in the solder used for the cell interconnections. However, the use of solder is also being phased out with the new busbar compression joining techniques and conductive paste materials. It's worth noting solder is used in hundreds of millions of electrical devices and appliances. There are far more toxic elements used in consumer electronic devices, mobile phones, computers, & TVs, which is why electronic waste or E-waste is a significant global problem.

Roughly 99% of the solar panels installed worldwide today are silicon crystalline and do not contain cadmium or telluride. Solar panels are benign, and even when damaged, they do not cause any contamination, as the cells are encapsulated within very durable polymer layers and contain no readily soluble materials. However, like all appliances, solar panels need to be collected and recycled at the end of life, which we discuss in the section below.

References

Detailed life cycle analysis of solar PV panels and systems

http://www.appropedia.org/LCA_of_silicon_PV_panels

https://www.researchgate.net/publication/264672000_Life_Cycle_Analysis_LCA_of_photovoltaic_panels_A_review

https://www.researchgate.net/publication/338384189_Review_on_Life_Cycle_Assessment_of_Solar_Photovoltaic_Panels

Manufacturing Silicon Wafers

https://sinovoltaics.com/solar-basics/solar-cell-production-from-silicon-wafer-to-cell/

https://pv-manufacturing.org/silicon-production/cz-monocrystalline-silicon-production/

Electrical Engineering and Technology - www.electrical4u.com

Recycling Solar panels

Since most solar panels installed over the last 20 years are still in use, there is not a great volume of solar waste. However, over the next 10-20 years, many systems will reach the end of life (EOF), and there is expected to be a very large increase in the volume of solar-related waste that will need to be recycled. Solar panel recycling is an emerging industry. Most of the materials, such as aluminium frames and mounting systems, are relatively easy to recycle. Most solar panel manufacturers are pushing to be more sustainable and are now part of the not-for-profit PV Cycle organisation - “PV CYCLE offers members and waste holders better access to take-back and ensure recycling rates above the industry standards.”

In Australia, there are several companies that will recycle old or damaged solar panels, including the Adelaide-based ReclaimPV. http://reclaimpv.com/

In Europe, the French waste management company Veolia opened the first dedicated solar panel recycling facility in southern France, which is able to recover and recycle 95% of the materials.

For further reading, here is a great article from RENEW about solar panel recycling.